If it’s PCB mounted and you can actually source a replacement that’s the same size, the best advice I can give is find someone who’s desoldered things before.

Rigid PCB mounted devices are IME a pain in the ass to desolder, and remove cleanly.

Yep. Starting to think this is out of my ability. Know anyone in the community that does this kind of work?

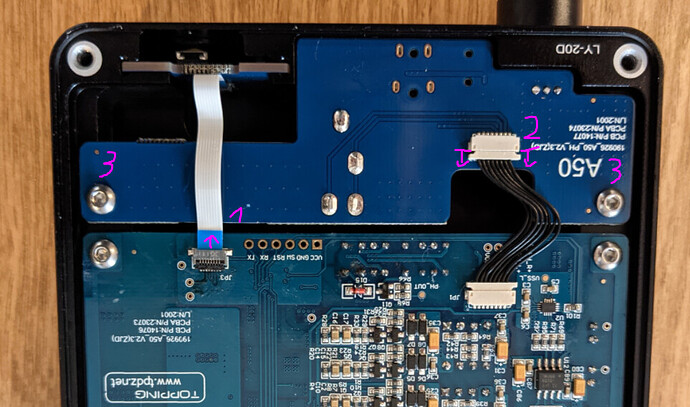

You should disconnect the flat cable gently unlocking it first and after remove the 2 screws so you can flip the small PCB on the top and be sure at 100% that the connector is a surface mount. But from what I can tell from the picture and the probably location of the connector it is a surface mount.

I’ll give it a shot. I appreciate your help

You’re welcome, if you don’t have experience with the surface mount components I suggest to watch some video online so you can understand better how to dial with it and with what you are dealing with before decide if proceed, the only positive thing is that the contacts of a surface mount connector are not microscopic like most of the SMT component so is one of the simplest STM component to solder.

That looks doable, actually.

Order of operation:

-

Using a pair of pliers/tweezers/etc. , pull on the blue tap, NOT the cable!

-

Stick a flat blade screwdriver in from the sides and gently push the connector out of the receptacle

-

Lastly, take out the screws.

To get the daughter board out, you may have to pull the knob of the potentiometer shaft.

Just remember to unlock the cable first by gently pushing the 2 small white plastic L beside the cable

Wow. Thank you for the guide!

Thank you!

You guys are great

While in there, would you mind taking some more photos?

Will do. Need to get back to work. Probably have time tomorrow or Sunday.

You may have to remove the larger bottom board to get enough room for the volume pot shaft to clear the front so you can remove the smaller board.

oh god. I might be out $150 bucks! But I’ll give it a shot

When I was a young man I wanted to be an electrical engineer. Should have fallowed that dream!

Take your time, here 2 video about the desoldering process and the soldering one

Chip quick is a good solution to desolder it if you have only a classic soldering station

Here some techniques to solder it

I hope they can help you to understand how fix it and also to decide if you feel confident that you can accomplish the mission

The volume knob can be a problem so don’t force the pcb but try to understand how is connected and how safetly remove the board.

Thanks again. Looks like I have a full weekend of learning. Which is great. Better than binge watching

netflix shows I’ve already seen. This kind of content fascinates me.

Regular solder and a bigger chisel tip will do the same for low pin count parts.

More that solder I will just use some flux, anyway different techniques same result. I thought to chipquick just because is user friendly

Sorry guys I chickened out! After watching videos and other research I decided this was above my skill level. Thank you for all of the input. I did learn a few things!