Makes sense. Serratus is the one I’d recommend to most people over Ripples. Glad we could put the curiosity to rest

I just want to piggyback here and say Jim is amazing. I reached out to him yesterday because the left bud on my Serratus started to have issues. In less than an hour Jim had gotten back to me with several options to resolve my issue. Hands down the best customer experience I have had to date.

A little brag post from me. I printed, assembled and tested my 1st good prototype of qian39 modified assymetrical shell today that’s main goal was to get good fitting bud design.

Edit: the design process started with having greatly modelled OG Qian39 stl file made by @Valphonics as a base reference ![]()

Afterwards the thought process was started at defining everything that was wrong with existing shells for me - MX500 is too tall creating painful feeling in my tragus, stem is located symmetrically in a way it is in collision with my tragus when properly sealed in ear. Qian39 is very good in terms of the height, but stem is also symmetrical causing the collision with tragus and therefore not allowing for perfectly proper seal and fit. It is also too long, so when I lay down on side of the head it sticks out too far from the surface so it creates a sort of “lever” and pulls the shell out of my ear.

I found an stl file of ear model on the web, scaled it to my own anatomy and took qian39 base model and moved the stem away from the central plane by several mm to move past the tragus.

After few trials and errors today I finally got to something usable. Generally the biggest problem with qian39 for 15,4mm driver drivers is that it is very “shallow” so magnets of the driver sometimes do not fit properly in along with the cable.

The prints went out fine, the volume of the material used directly is around 5ml, but there is always a residues, so in total I would say around 15ml of resin was used for both (0,25$ cost per ml of the raw material)

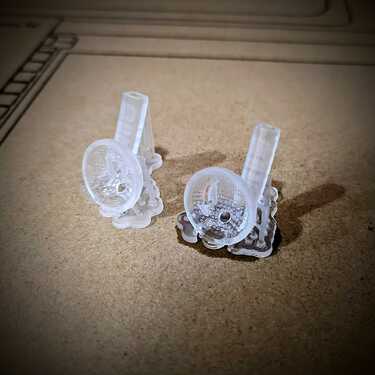

Raw printout with support

Curing process along with not important work related stuff ![]()

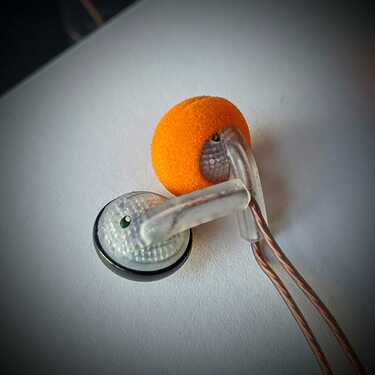

First assembly (the surface is just roughly sanded down):

They do fit me like a glove (or almost IEM like) - I would be brave to say I could run in them without loosing seal!

in regards to the sound - there is artificial “noise” added to the inner cavity for extra dispersion (so like a dumbed down way of what @Rikudou_Goku is R&Ding now) which in my opinion helps a lot with the soundstage and the “size” of the notes.

The bass is not perfectly heavy still, but now I am only testing it with 32Ohm Vocal centric PET fostex driver and open bass port. The driver itself is not very bassy by itself - it has problem with bass wherever I use it. I used just a dense paper filter on the driver itself - no proper foam material would fit in the shell anyway (maybe just covering bass port).

What is also not perfect is the resin used is not desired to be in prolonged contact with skin (or at least was not tested for that), so I could not use it for testing on anyone by myself. Once I buy some biocompatible resin it would be safer.

Niiicce! I know @Valphonics has his own 3D designed earbud shapes as well, so I’m sure he’d find this interesting as well.

Were you able to get the walls thick enough to be sufficiently stiff? MX500 shells, while feeling light and flimsy, are made from stiff and somewhat thick plastic.

Well I am the original designer of this shell with my name clear on it, so its somewhat interesting!

Just a little bit of credit would be appreciated

Hi mate,

I had your design of Qian39 in .stl fille in the beginning, but truth to be said I needed to completely redesign the parts from the scratch to be usable in my CAD and with my requirements redoing all the measurements on OG shell IRL.

But, yes - sorry - your work was a big part of the initial work, should have mentioned you in the post, as that was great kickstarter ![]()

Walls are 1mm and stiff enough for normal usage and snap fit of the faceplate. But resins are not particularly tough meaning their impact resistance

I am so excited to see what you have in store for the future, dude. This process is amazingly interesting to me - I absolutely love the clear resin housing, I know resin is not the safest material for direct skin contact (my wife has a lot of experience with resin pieces) but once you get your hands on resin that is safer for direct contact on skin, I think the clear resin opens up opportunities for different design using Mica powder and other types of textures and what not.

Again, my wife has the experience with resin and I remember all of the pieces she made back in the day for customers. They were all so beautiful in their own way. Here are some my favorites, your post has me reminiscing ….

Reminds me a lot of the hand-painted Kinera shells (which I love)!

Absolutely - Kinera make some of my favorite Shell designs in the entire industry. They always hit. Being so close to these pieces and the process, taking the photographs and being taught how to make them, really helped me appreciate the process so much more. These particular pieces are all hand mixed and poured by my wife, she used different mica powders and alcohol based inks to create the colors and designs. She would painstakingly use a tooth pick to swirl specific colors and glitter to create this amazing depth effect … my photos absolutely never did them Justice but I always tried my best.

Man, this thing is EPIC!!! Given we have similar ear shapes (dimensions may be different, though) , I find your work reaaaally interesting (that plus following your tuning researches).

Great work. Don’t give up, you will certainly end up very proud of what you are achieving here. ![]()

It looks really stunning! ![]()

Unfortunately unless I buy my own DLP printer to use at home I would not be able to test any custom aesthetic resins. And I won’t buy any resin printer for home use unless I move out from my apartment to proper large house as it is too dirty to handle and dangerous with little kid wandering around in small space ![]()

The printer I use is for my work in principle, it is very closed (opposition of open source) system, so any modifications in the formula are hard to enforce in the printer settings and are costly as I need to have the resin tank fully cleaned for that particular raw material or use completely new which is 200$ each. But when someone reaches Rikus or Jim’s volumes of sales they may be able to reach out to some OEMs in China for custom solution which would be cost effective ![]()

Thanks a lot for kind word! ![]()

If I manage to get a safe resin I would like to ask you if you would be my trial patient of the design. If you would agree of course (as you are in EU and with potentially similar anatomy) ![]()

Sure man, I’d love to test DIY stuff!!

If I had the choice, I would reincarnate as a guinea pig ![]()

I totally get the difficulty in getting a more productive line for DIY bud production, no doubt. Normal, non-medical grade, not skin safe is actually quite expensive if I remember correctly. $100 for two bottles to mix together to begin the chemical reaction, plus molds, decorative material ect. Can add up quick. Those two bottles of resin material only make you so many items too - plus, factoring in mistakes in the process and having to chuck those shells or resin items … that’s not even mentioning the machine needed. I can only imagine.

Still, it’s absolutely fun to play with the idea!

Yo I‘d absolute buy one of these in a heartbeat as a cigar holder a shaving soap mug. Those are beautiful works of art.

Dude, that means so much to us - I showed her your comment and she said that is so special - she hasn’t made anything resin related in years, you do actually need a designated area, sealed off with proper air flow + a gas mask to do it safely. We are moving to a larger apartment this coming month and my wife said she’d like to start doing it again … who knows.

Jesus H Christ, can I give a simple protip:

Fresh foams save buds. Damn some of the buds I have feel revitalized with a simple foam change

Just a short follow up on asy qian39.

As they say if you can’t beat them, join them.

My fight against Vido’s SQ with this custom shell and lack of good drivers on hand (waiting for some really cool lines to arrive at the moment) was almost lost completely - I had a pretty decent sounding bud, but not sounding better than Vido.

Then I found out that I can transplant Vidos drivers to my shell, why not! With medium HS tuning foam they fit perfectly in shell, have nice rumble, ok vocals and smooth treble. All in all those are very capable drivers and amazing value for money (I don’t think I bought better drivers by themselves than those assembled and with free cable).

I am also after 30mins walk with those in ears - not even one correction of fit was needed throughout. It is such an amazing experience I never had with any bud up to date. And I am very envy of those who can go along with their MX500 like that!

Anyone ordered either one yet?..