Initially when I clicked the link, there was no tin lead ratio in the specs. After doing some digging, I found out that it is 60/40, which is perfectly fine for your use case.

How much soldering experience do you have?

Leaded/lead based solders are easier to work with and give more forgiving joints.

How heat sensetive are the parts arround what you solder?

High copper and silver contents push the soldering temperature up a lot, check spec sheets of components (when working on a PCB) for acceptable temperatures and times.

Working near plastics, my rule of thumb is melting point - 50°C for 5 seconds, every 5 minutes.

Resin, flux, etc.

Is not a “nice to have” or optional. This is what gets the surface contamination out of the way and makes the metals stick.

The small puff of smoke when you touch the solder to the iro is your flux. When that is gone, clean it off and start over (or add flux from another source).

The joint

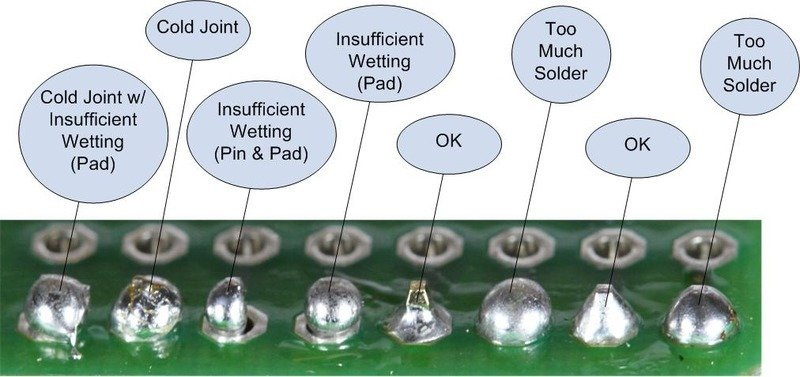

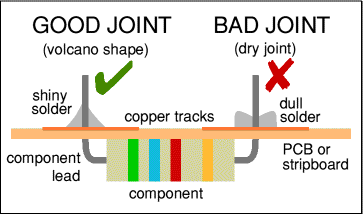

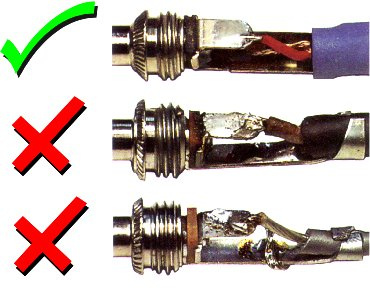

Hard to describe, here are some examples:

Testting the Joint

Any solder connection where your multimeter reads more than 50mOhm (= 0.05 Ohm) is bad. Ideally it reads 0.

Having done soldering since I was in high school (20 years now) I endorse everything @MazeFrame has said.

You can get rosin core solder and not get flux seperately. Do not get leaded solder. It works better generally but the fumes should be considered toxic. You really only should use it with a respirator and a air evac unit. It will say clearly if it has lead or is lead free.

The most important part of having a good experience with soldering is not the solder (generally), but the iron. Only use a soaking wet sponge or a soaking wet paper towel to clean the tip. DO NOT SCRAPE IT WITH HARD METAL

After you’re done, use a decent amount of flux and solder to “tin the tip”. Then let it cool with a little solder on the tip. Store it that way, it helps protect it.

When you need to heat it up again take the old solder off as soon as you can. Pushing a lot of solder on to the tip will allow the flow of the solder and the flux to really clean it. It will then be ready.

You will burn yourself, it sucks, but it’s not too bad. Hurts for a day or two.

To clean the flux from the solder joints once you’re done (which you should do as it’s slightly corrosive) you can use iso alcohol. 99% -90% is best but 70% will do in a pinch.

All the examples in images are good ones.

@Hazi59 So the Hyper Tough Rosin solder should be fine?

Sadly, I do not have a multimeter, and don’t know if I have access to one without going and blowing dough on one…

Well, the iron I have is the one I pictured above. Yeah, it’s a cheap one, obviously, but I’m also not doing critical board component level work here. On the other hand, I know that wet sponges are OK, but something like this is prefered (from my understanding):

https://www.amazon.com/Aven-17530-Soldering-Coiled-Cleaner/dp/B00LQG47V0/ref=psdc_13837401_t3_B07FP3P74Y

(I know this Hakko exists, but at $20 more? I don’t know…)

https://www.amazon.com/Hakko-633-01-Iron-Holder-Cleaner/dp/B000TGNWCS/ref=psdc_13837401_t3_B00LQG47V0

Would you say it would be best to buy flux seperately as that precaution if things get screwy and I have to redo a solder point(s)?

Something like this:

https://www.amazon.com/SRA-Rosin-Paste-Flux-135/dp/B008ZIV85A/ref=pd_bxgy_3/138-9065197-4465330?_encoding=UTF8&pd_rd_i=B008ZIV85A&pd_rd_r=eef1246c-61c7-419e-af0e-73f561e5d6a2&pd_rd_w=YDKaI&pd_rd_wg=3ArFE&pf_rd_p=ce6c479b-ef53-49a6-845b-bbbf35c28dd3&pf_rd_r=RXR4CDQ09ECJK3ZSR9EX&psc=1&refRID=RXR4CDQ09ECJK3ZSR9EX

I know Luis Rossmann sells the stuff he uses, but I am not sure I wanna spend $30 on something I’m only gonna use a tiny amount of, or wait for however long it will take to get here.

Found this as a guide. Looks good to me, but I’m willing to hear the experienced individuals thoughts

Edit: Considering modding the cable as well by slapping one of these where it was attached to the headphone:

https://www.amazon.com/Ancable-Connector-Protection-Headphone-Earphone/dp/B07MMWWSCW/ref=pd_rhf_ee_p_img_7?_encoding=UTF8&refRID=PD6QZDYVKKSF1862ZQXT&th=1

You do not need a brass coiled type to clean if you aren’t doing a ton of work. A soaking wet paper towel will do. I use it all the time to clean my tip if I don’t want to break out all my soldering gear.

The iron you have seems fine, it will just take time to heat up, reheat, and will need more patience. 35W is pretty low though, it will take more time to heat up bigger things (like the ground). But it can be done, just don’t rush it. Don’t think it will go as fast as most tutorials (Like Loius’) as they all basically have great irons.

For example, most cheapy soldering iron kits come with 60W. This is the lowest/cheapest I can personally stand to solder with. 35W will take time, just be patient with it.

I would get access to one. They are also really cheap at Harbor Freight.

https://www.harborfreight.com/7-function-digital-multimeter-63759.html

https://www.harborfreight.com/11-function-digital-multimeter-with-audible-continuity-61593.html

If you have a solder junction that’s cold, it could add a decent amount of resistance. As you don’t have a ton of experience looking at solder joints, you may not notice a cold joint. Extra resistance will mess with sound quality. It may also make one side sound different then another. Too much solder may pickup unwanted EMF (outside noise) as well, so having clean joints is important in audio.

No you would try to pull off the solder with a wick, or clip the wires and reset. Don’t waste money on a cheap solder sucker (the syringe looking things), all of them are garbage. Most people new to soldering that get flux separately use too much. You have to clean all of that and it might flow to somewhere you don’t want. I have never needed to use a can of flux for most soldering. I only have needed it when I’m doing surface mounts with a heat gun.

Also, I know some people don’t believe “burnt/overheated solder” can be a thing, but I do. So it’s generally better to reset, instead of trying to fix something.

I would look around the garage/attic/basement for old electronics, open them up, and practice on them. Then once you feel more comfortable, move on to your actual project. The older the better as newer stuff is almost all surface mounting, but what you should start off on is through-hole mounting stuff.

Surface mounting is what Loius normally works on and is a completely different beast to through-hole/standard.

Cheapy Ebay ones will do. No need to get a Fluke when you have like 2 measurements each year ![]() .

.

More than good enough, yes.

I have a flux pen and some othe versions on hand. Better safe than sorry.

I mean… Part of my thought was “eh, it’s $9, and I don’t already have a stand/holder”.

Okay… So higher wattage = worse? Maybe I’m just not understanding correctly… I mean, I’m not looking to pick up a soldering station like the Hakko that Luis uses by any means, let alone a different iron, less i end up with something that just can’t do the job.

Sadly, I don’t have access to a Harbor Freight without going deeper into town then what I am able to get a ride to. For a more budget offering, what should I look for in a Multimeter? I’m actually going to WallyWorld (WalMart) today, so I may be able to check to see if they have one there.

Okay, the Yes or No seem to be where you and @MazeFrame seem to differ (if I’m understanding correctly). I wasn’t meaning to say using the rosin to remove the old solder, I get that’s what the wick is for, and I’ve seen Luis rag on the solder suckers enough to know how shit they are.

If I was going to buy another iron, I would probably go for this one for cost, and Luis really liked it.

No the lower wattage, the longer it will take to get up to the heat needed to flow solder. 35W is low, but usable if you’re patient. A 60W will hold it’s temp longer and will take less time to reheat.

Getting a slightly better one isn’t absolutely needed, but you would be better served by getting a chepar higher wattage and a $50 multimeter

It might have one, yes. I wouldn’t spend more then $15-ish on one as you aren’t going to use it for much. One without a digital display is probably fine if you’re just checking resistance.

that’s what made more sense to me, but wanted to be sure. Again, if I would go buy one, it would probably be the TS100 I linked (though I could see how I could get easily confused with it.

I just edited, check my edit.

With this being the only real soldering job I plan on doing, I can’t see buying a better iron being that worth it if this one will get me by. I can understand a cheap multi-meter from the points y’all made about it though.

It looks like they would actually have three. All ~$15-20

Actually, in your case as you care about minute amounts of resistance, I would get the analog one out of those three.

I’d expect it to be fully analog inside, so it may be able to mesure more accurately. Cheap digitals don’t really get a good resolution for tiny readings.

None of which I just typed might be true though. As it’s made of chineseium and has walmart level quality assurance.They literally might be digital on the inside and then reconverts it to analog for the needle.

Damn, out of stock. Found this on Amazon though, how’s it look?

https://www.amazon.com/dp/B00002N5EX/ref=cm_sw_r_cp_apa_i_hpclFbDQAJKZP

You really do want a meter.

All you really need for cables is a continuity tester, if the solder joints look good they usually are good.

Any $10 meter will probably be good enough.

I have cheap and expensive meters here, and I’ll usually use what’s nearest to me when I need it, unless I really care about the result, or don’t believe it.

A 60W Iron makes soldering connectors especially larger ones a lot easier, it’s less of an advantage on small PCB mounted components. The issue with lower power irons is the area around the joint will soak more heat because the heat has to be applied longer and is therefore less localized. That makes melting plastic parts of connectors very easy for beginners.

I prefer soldering iron tips with flat areas rather then conical ones, but YMMV.

I think solders been covered, pretty much any rosin core 60/40 is fine, do not use leadfree, and higher silver contents aren’t worth the additional cost/skill requirements for most Jobs.

I have 60/40 and some Cardas higher silver content stuff, I use the latter in audio, but only because I have it on hand and I don’t mind how it flows. If I ran out, I’d use the 60/40 and not worry about it.

The consensus seems to be to go buy a better iron.

Depends, if your doing a couple of things or just trying things out to see if you enjoy it, use what you have.

If you see yourself doing a lot of soldering, buy a decent iron, it makes the whole thing a lot more enjoyable. I have a Hakko, I bought 20 years ago and still use, so they’re not something you go through yearly.

I just see little shit like this once in a blue moon. Even so, especially with how much Luis liked it, I’d probably get the TS100 that Luis reviewed for $70

Yup. Good for when you can’t dip/drip flux on the part in question. For wires, having a tup do dunk the ends into is nicer.

Ended up pulling the trigger on a few things…

I’m gonna stick to the iron I have right now, and I simply wasn’t comfortable pulling the trigger on solder I wasn’t totally sure on, so I ended up buying what @Hazi59 reccomended.

The multimeter was $10, but had good reviews, and was analog, something @pixelnull pointed out might be benificial (if it’s purely analog).

I snagged the stand cause it was cheap, had good reviews, Prime shipped, and had the copper coil cleaner (though y’all said it was unnecicery, I just thought it was a nice to have).

I snagged the 3.5mm connectors for the spring strain relief, price, and thought of still having a use for the stock cable.