The topic states V2, because I wrote up my first attempt in the Koss KPH30i thread a while back, which you can find it here in this link.

Now that we have a DIY section of the forums, I thought it would be good to write up the second attempt, which I’ve refined from the first. The main problem I had modding the KPH30i was that I could not permanently epoxy the two halves of the housing together, because you need to open the housing if you had to change the foam. The result was a weaker adhesion between the plastic, epoxy and the smooth all metal MMCX connector. So the connectors were just being pulled off the plastic given MMCX has a very tight hold.

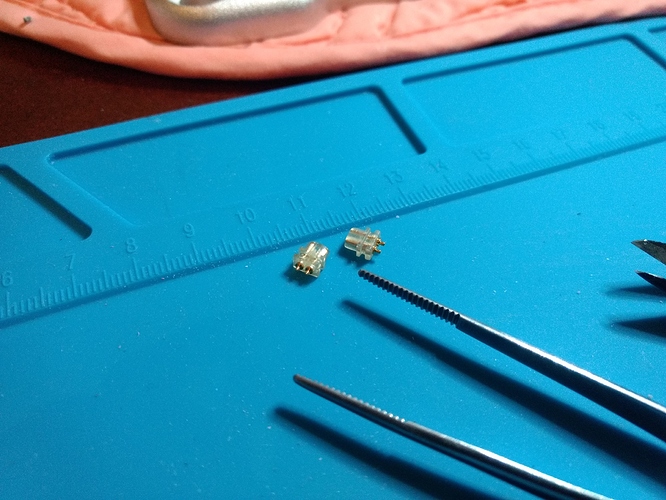

The solution was to switch to 2-pin connectors instead. Not only do the 2-pin connectors have a plastic housing, they also have a groove which is important as I’ll demonstrate later.

You can get these 2-pin connectors on Aliexpress

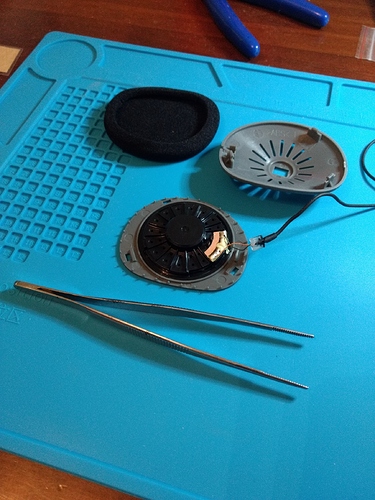

Now first thing first. Disassemble your KPH30 following these steps.

- Do NOT pull the driver housing from the headband. You will permanently damage the headphone.

- Pull off foam. If you’re swapping pads (i.e to Yaxi PortaPro Pads), you can risk destroying them. I have a pair of forceps that I gently pull the foam free of the teeth that holds the foam in place.

- There are 3 tabs that hold the housing together. Push the tab AWAY from the center to release it. Do this one by one gentle as they are plastic and can break if you’re too forceful.

- Once the housing are separated, you have the driver side with attached wire. The other side will be a piece of foam, remove that. You will find another pair of tabs that hold the second half of housing. Push them together to pop the housing from the headband.

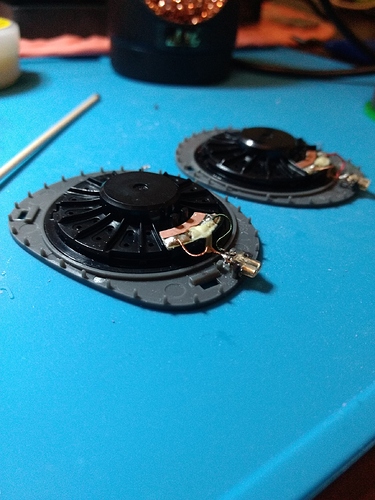

If all goes well, you should have something that looks like this.

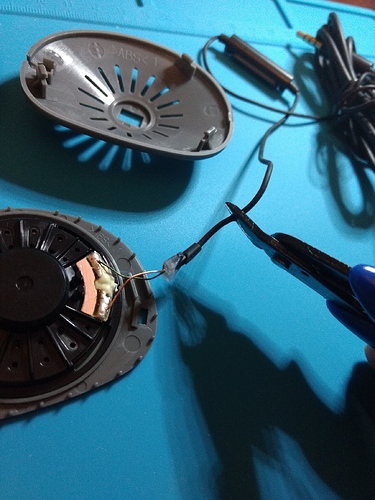

Next, snip the cable. This is the point of no return. In the picture, I cut below the white plastic mold thinking I could pull more wire through the cable like in the PortaPro or KSC75’s. No Koss permanently fixed the wire at the translucent end. Just cut there instead.

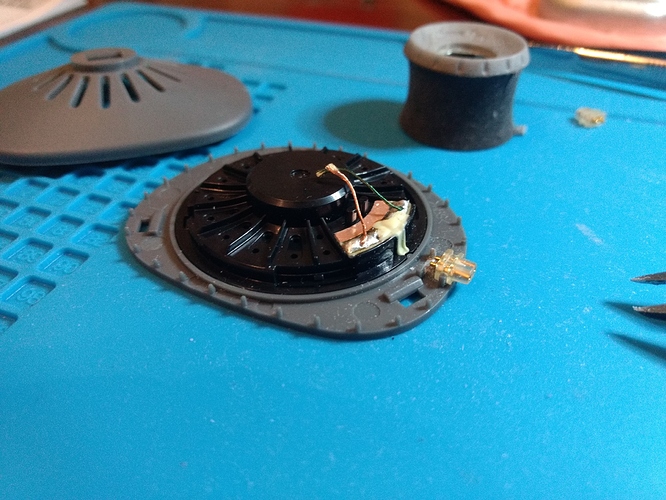

Using a dremel or precision wire cutters (I prefer the wire cutters for this part), enlarge the hole of the housing so it fits the 2-pin connector. Then this is where it differs majorly from my first attempt. There are 2 horizontal plastic bits below the drivers. Instead of cutting them away. You make gap large enough to slide the 2-pin connector grooves right in. You can do this by either sanding it down with a dremel, or using a sharp wire cutter, carefully cut 2 ends, then rock the plastic bit back and forth until it comes off cleanly. The latter method is much more risky because if you aren’t careful, the ends you want to keep could come off anyway.

In any case, if you’re successful, the 2 pin connector should slot right into the housing. Allowing a more secure base for you to epoxy like so.

With the enlarged hole for the connectors, it should be a snug and neat fit like so.

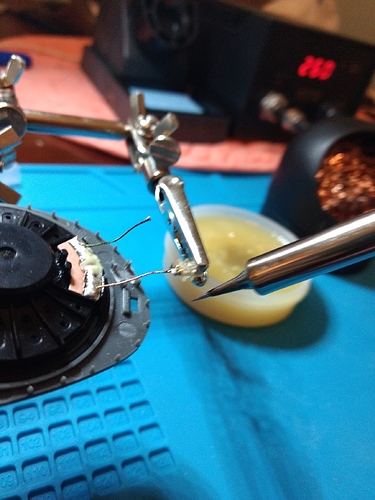

Now all that’s left is to solder. I can’t help you with instructions because I am a beginner in soldering myself. However, it should be said that the 2-pin connectors I use have short ends to solder. So a fine tip soldering iron helped a lot here.

If you have a multimeter, test them after you solder. If not like me, I plugged them into a source (observing polarity: Coloured = hot. Copper = ground) and played left and right channel test.

When that checked out, I epoxy-ed the connectors to the housing. This is another point of no return so you better make sure your soldering holds well.

Make sure you leave it to cure for the appropriate amount of time before reassembling it (usually 24 hours). Just leave it the hell alone and resist the urge to marvel at your mad skills. You don’t want to give any excuse for the epoxy to come off after you’ve reassembled the pads.

If you’ve been good, put it all back together, with new pads and you have yourself KPH30i’s that can use any 2-pin cable you want instead of being anchored to the stupid wire it comes with.

So there we have it. I hope that’s comprehensive enough for you to attempt to mod the KPH30i on your own. You do need the right tools for it, but it’s not overly complicated. The goove/slot method should work better to deal with the constant stress of having the wires being attached and detached. Also using 2-pin means less force is needed to remove or attach the cable.

I still think the PortaPros are easier to mod because they are simpler to take apart, but I like both sound signatures, so I don’t mind owning and modding both. The best thing about the detachable cable mod is that you don’t have to use cables. If you’re a crazy person like I am, you can also turn the KPH30i wireless if you have the right gadgets at your disposal.

Cheers and good luck.